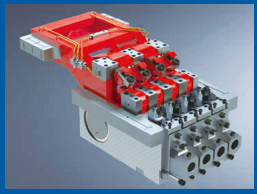

Krevere 8-Station Cold Heading Machine: Suitable for the high-speed forming of bolts and non-standard special-shaped fasteners, it offers advantages such as high precision, high efficiency, and low energy consumption.

This 8-die 8-blow cold heading machine is a newly upgraded model from Chun Zu’s cold heading series, offering higher efficiency and greater stability.

The following information includes the product specification sheet, detailed product features, configuration and material list, sample products, performance advantages, and application fields of our cold heading machines.

Scroll down for more details!

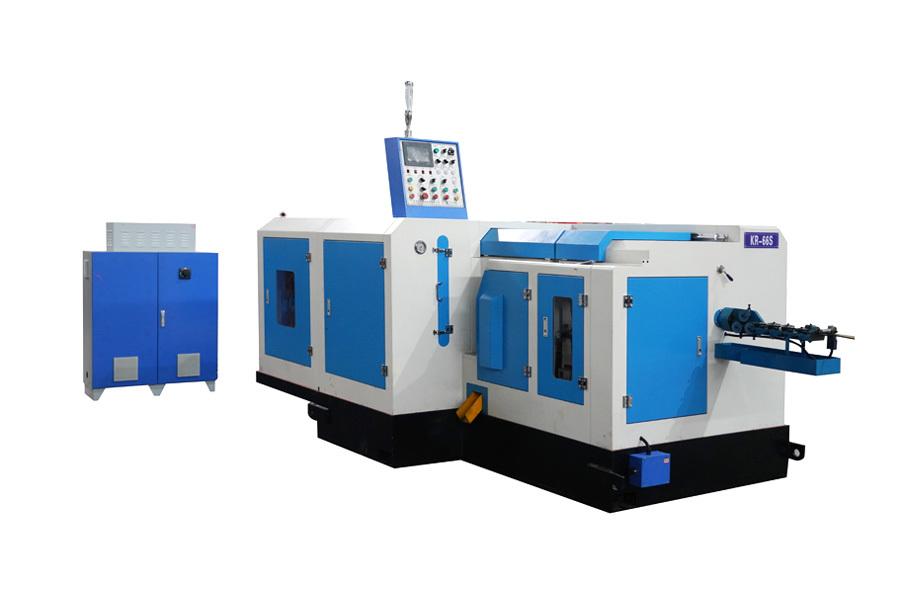

Product Specifications

Product Details

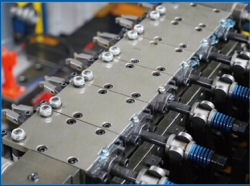

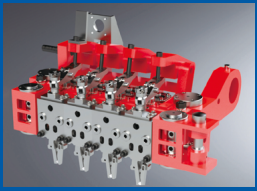

Swing Pneumatic Clamp:The clamping force can be adjusted according to the material properties. During short-inch operation, the first set of clamps is automatically released, while the last set transfers the finished product onto the internal conveyor belt, ensuring the integrity of the finished parts.

P.K.O. and K.O. Structure:The P.K.O. and K.O. mechanisms are controlled by a digital servo motor and can be remotely adjusted for debugging. This system simplifies maintenance and ensures high-precision manufacturing of finished products.

Clutch: Equipped with a pneumatic clutch and pneumatic brake to avoid the starting current being generated repeatedly, making it convenient for parking and reversing, and improving the efficiency of mold debugging during installation.

Pneumatic clamp: It can be quickly adjusted centrally, used simply and stably, and the clamp can be freely changed with an exchangeable (optional) type.

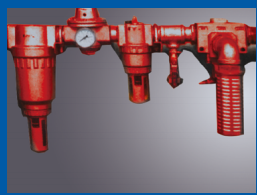

With high-grade configuration, easy adjustment, and a centralized compressed-air system.

A powerful cut-off mechanism is directly driven by the crankshaft.

The high-precision main slider is connected with the rear-wing design to make its travel more stable and accurate. The QT600 material offers excellent wear and heat resistance. The inner bushing is thickened with a ZQSn10-1 copper sleeve to ensure precision and prolong service life.

Each station of the K.O. structure can be adjusted independently, and the last station can perform the reaming action by adjusting the cam position or replacing the cam. It is equipped with a safety pin for pressure checking.

By the cylinder-controlled pawl mechanism, the shaper lifts automatically, eliminating noise. The electromagnetic valve controls the cylinder feeding intermittently, allowing for larger product sizes and expanding the machine’s production range.

The straightening machine allows the material to enter and exit automatically. It features a horizontal alignment plane for easy cable installation. The self-feeding system loosens the wire to protect its surface from strain.

The whole point of the tubing to achieve a single tube of oil independence,to ensure uniform film,hydraulicequilib-rium at high speeds.production specifications.

Product Configuration Material List

1. Machine frame: QT500-7 nodular cast iron

2. Main slide: QT600-3 nodular cast iron – through-hardened and high-frequency hardened on both side faces

3. Main crankshaft: 42CrMo forged steel – quenched & tempered, plasma nitrided to 58–60 HRC

4. All cams, rollers and guide rails: SKD-11 (D2) tool steel – vacuum through-hardened

5. Gripper plates: aerospace-grade 7075-T6 aluminium – hard-anodised

6. Wear parts: 38CrMoAl nitriding steel – gas nitrided

7. Tin-bronze bushes inserts: ZCuSn10P1 (CC480K)

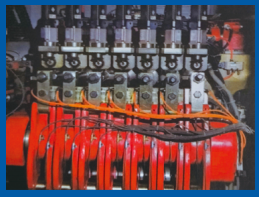

8. Electrical package: Schneider Electric (France) – inverter, PLC, HMI with USB port

9. Bearings: NSK (Japan), 100 % imported

10. Lubrication pump: Chyn Tien (Taiwan), internationally interchangeable

11. Main motor: Wannan Motor (China), domestically interchangeable

12. Over-running clutch: OMPI (Italy)

13. Clutch solenoid valve: SMC (Japan)

14. All springs: Tohatsu Tohats Spring (Japan)

15. Built-in upset-force anomaly detection (domestically leading technology)

16. All fasteners: grade 12.9 high-tensile bolts

17. Warranty: 3 years on main slide and crankshaft

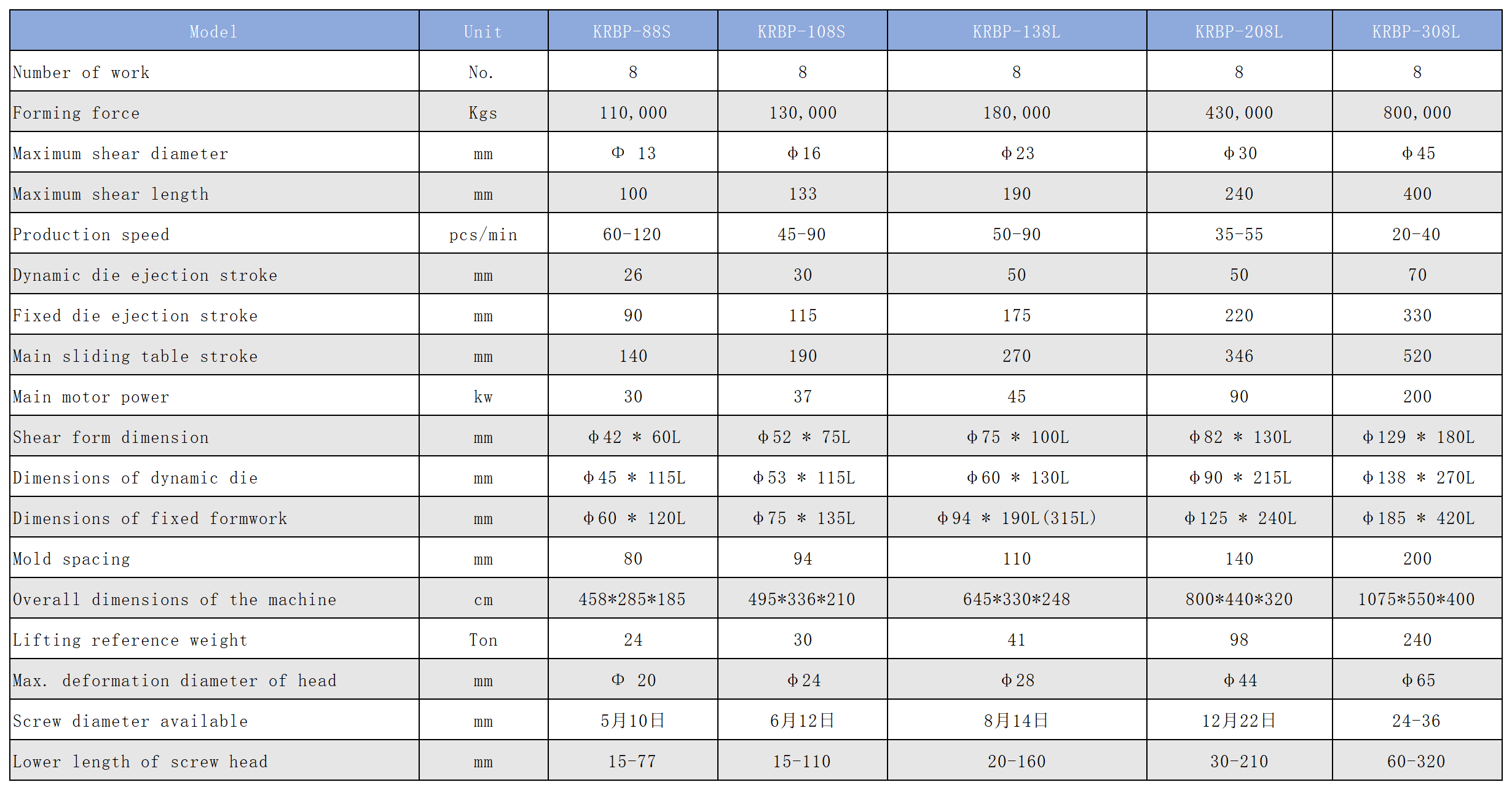

Production of Products

This machine can produce various special-shaped fasteners.

Product Advantages

Performance Advantages of Cold Heading Machine

High Precision

Rigid body and precision guiding system ensure die alignment, dimensional stability, and minimal secondary machining.

High Efficiency

Multi-station forming completes cutting, upsetting, extrusion,and heading in one cycle; speeds reach hundreds of pieces per minute.

Wide Material Compatibility

Processes carbon steel, stainless steel, alloy steel,copper, aluminum, and more; die design adapts to different materials.

Energy Saving & Material Efficiency

Cold forming reduces energy use, improves material efficiency, and minimizes waste.

Stability & Durability

Integrally cast body, high-strength components, and imported bearings ensure low vibration and long service life.

Intelligent Control

PLC system with touch screen allows easy operation, real-time monitoring, fault detection, and automation integration.

Easy Maintenance

Five advantages of equipment

High utilization rate of steel

High production efficiency

high mechanical performance

Suitable for automated production

Widely applicable

Classification:

Key words:

Related Products

Product Consulting

Telephone

Hello, what can we do for you?